- Home

- Milling

- Milling Machines

- EUROMAX ELEMENT 5 AXIS – DRY

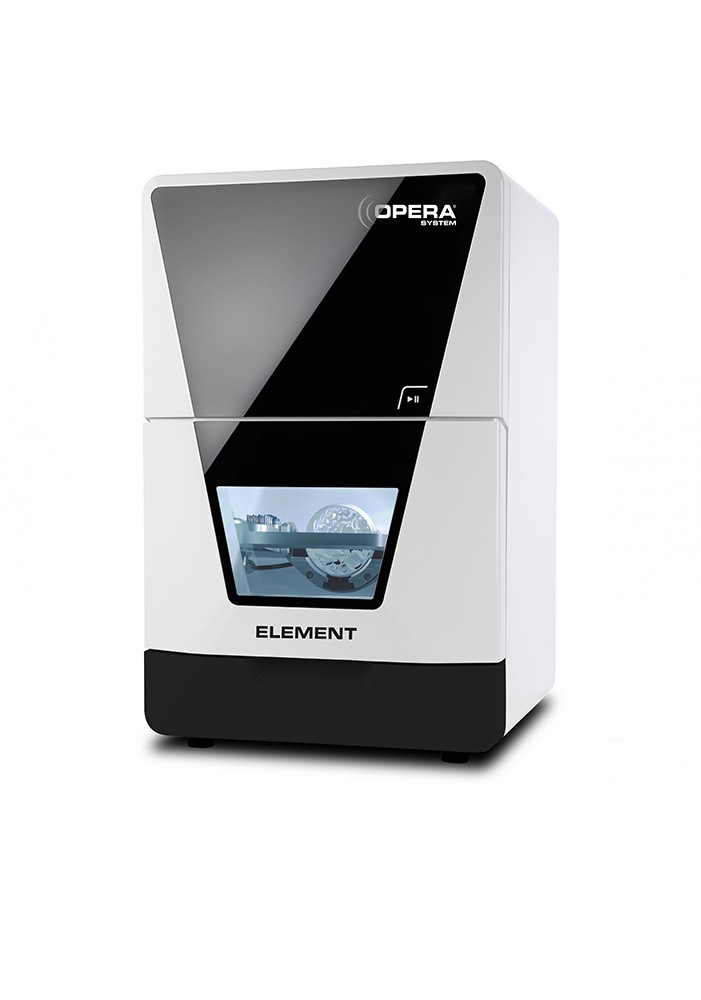

EUROMAX ELEMENT 5 AXIS – DRY

ELEMENT offers flexible, efficient, and cost-effective 5-axis dry milling with no need for compressed air, reducing operating costs and allowing free placement in any workspace. Featuring an automatic 17-tool changer, intelligent AIR TOOL for dust removal, and seamless CAM software integration, it ensures precision, ease of use, and maximum workflow efficiency. Perfect for digital dental restorations, ELEMENT combines innovation and simplicity in a compact, high-performance design.

Starting at 25 000€ (Final pricing may vary depending on the options. Request your custom quote today!)

Maximum Efficiency & Ease of Use

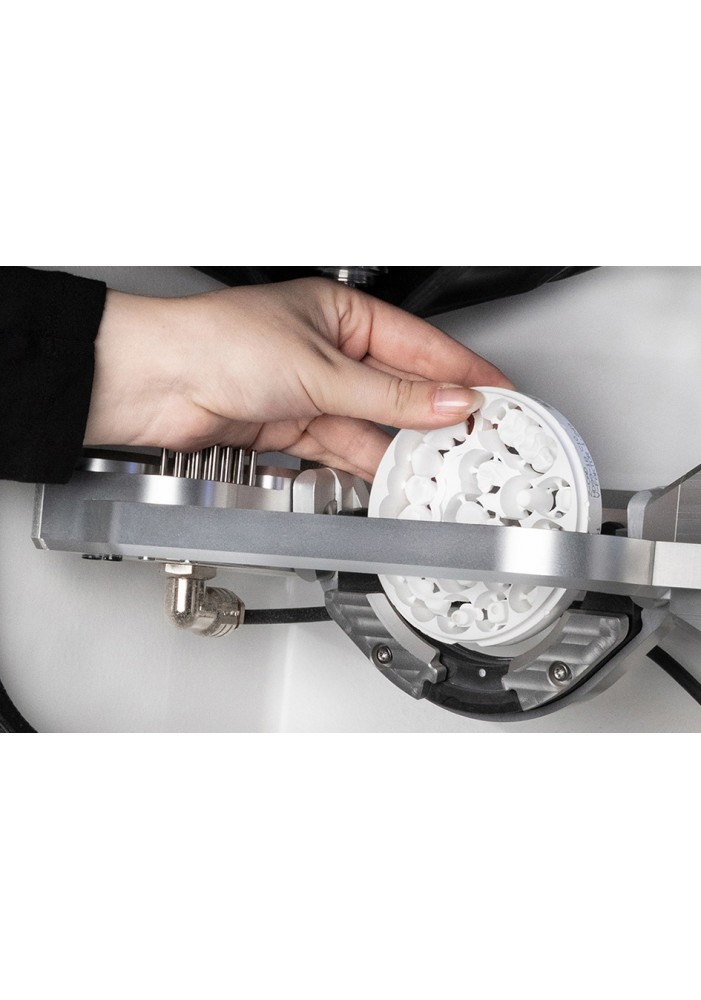

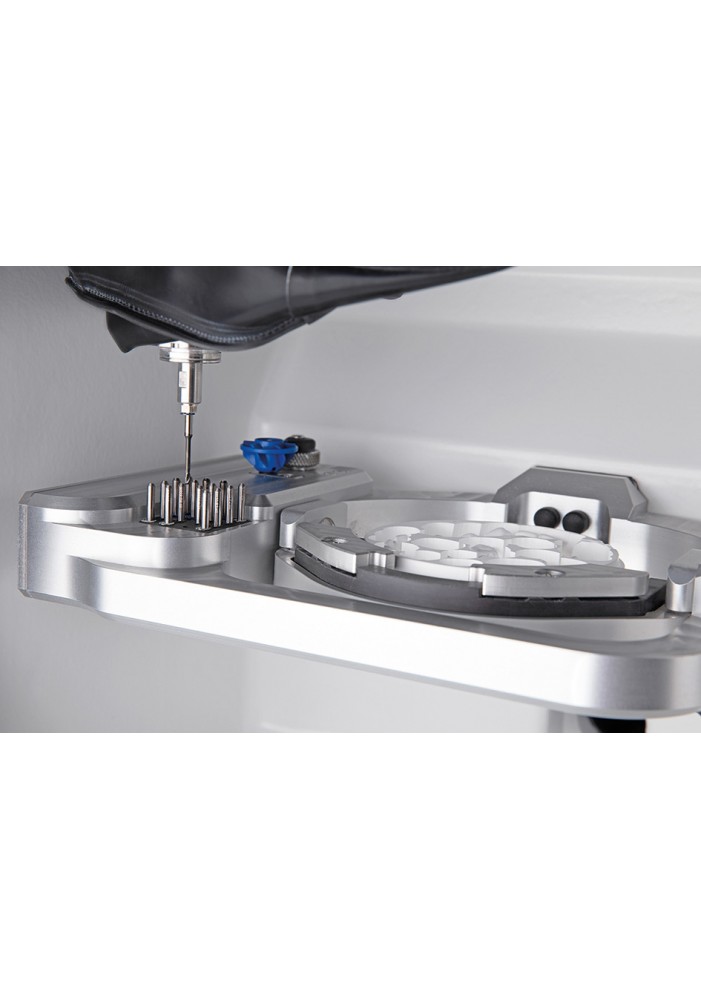

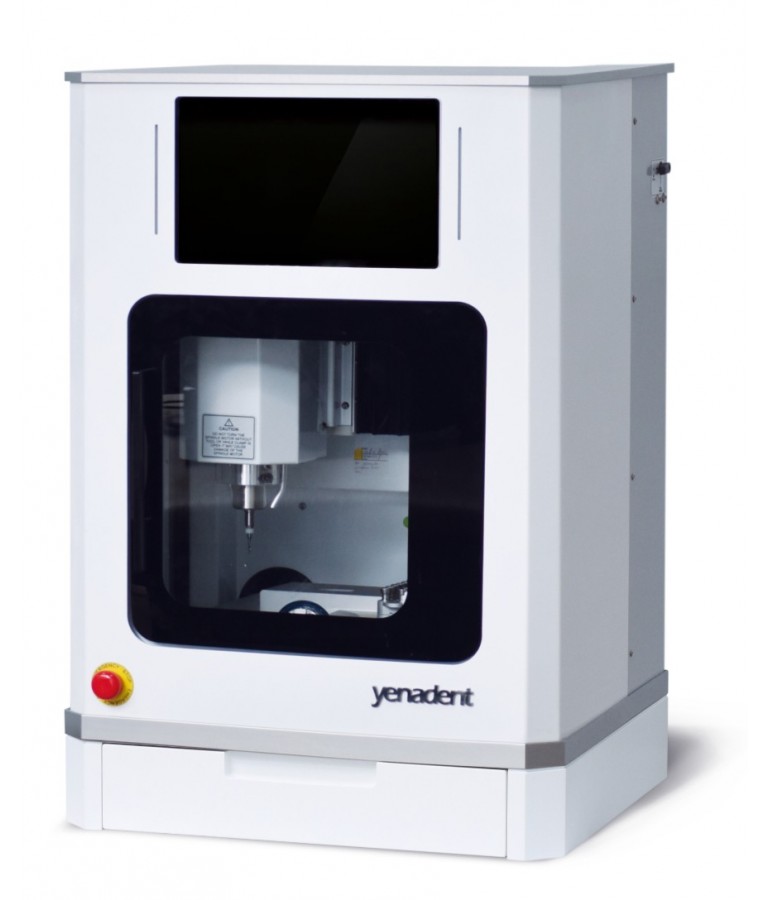

ELEMENT offers 5-axis dry milling with no need for compressed air, reducing operating costs and allowing flexible machine placement. It features an automatic tool changer (17 tools), optimal disc utilization, and color-coded tools for easy workflow management. The compact yet spacious design (43 kg) ensures seamless integration into any lab.

With the included CAM software, you can start production immediately, making digital dental restoration simple and efficient.

Innovation & Freedom

ELEMENT’s patent-pending AIR TOOL eliminates the need for compressed air by generating high-speed airflow to keep the workspace clean. This means no external air connections or built-in compressors.

The machine supports both disc and block machining, with an optional 6-block holder for greater versatility. Despite its compact design, ELEMENT provides a generous work chamber, ensuring maximum flexibility and ease of operation.

Technical Information

| Application Fields | Dry machining |

|---|---|

| Dimensions | 472 x 484 x 734 mm |

| Weight | ± 43 kg |

| File Format | STL |

| Number of Axes | 5 axes |

| Screen Ports | DVI, HDMI, and VGA |

| Tool Changer | 17 tools |

| Machinable Materials | Zirconia, Wax, PMMA, Peek, Acetal, Nanoceramic |

| Axis Movement | Rotation axis A: 360 degrees — Rotation axis B (5th axis): ± 35 degrees |

| Repeatability Precision | ± 5 microns |

| Rotation Speed | Up to 60,000 RPM |

Available Options

- YDO25KW Option: 2.7 kW Spindle for D15, D6, D14

- 60,000 RPM spindle

- Water-cooled with independent air conditioning

- YD15OW Option (D15 & D6): Water-Based Machining System

- Designed for ceramic milling

- Comes with a holder for 3 ceramics

- PRE6 Option: 6-Premill Holder for YENADENT

- Compatible with D15, D43 (Gen 2), and D6

- Supports Yena premills only

- Calibration management via Mayka

- O Option: Eaton Protection UPS

- EATON 1200 kVA

- KitD: Starter Kit

- Select consumables from the catalog (Discs, tools, etc.)

- BO250: Bofa Dental Pro Central Suction System

- 3 m³/min airflow

- Brushless motor for durability (carbon-free)

- HEPA filter

- CMP011: Puma Compressor

- Dual-cylinder compressor (220V)

- Max pressure: 8 bars

- Power: 1.5 kW

- Noise level: 56 dB

- Dimensions: 800 x 605 x 865 mm

- Suction flow rate: 304L/min (restored flow >100L/min at 8 bars)

- 60-liter tank with air dryer

- MD01: MD Core – Mayka Dental MD5x

- MD Core version 5-axis (for 1 machine)

- MD04 Option: Multi + Premills + Single + Multi Library

- Implant milling for zirconia, titanium, PMMA, and premills

- Supports T-base, multiunit, and direct implant machining

- Includes Yena bridge implant library